Our Technology

|

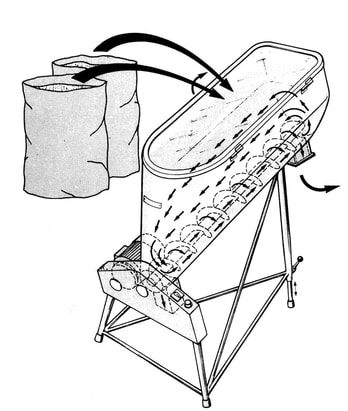

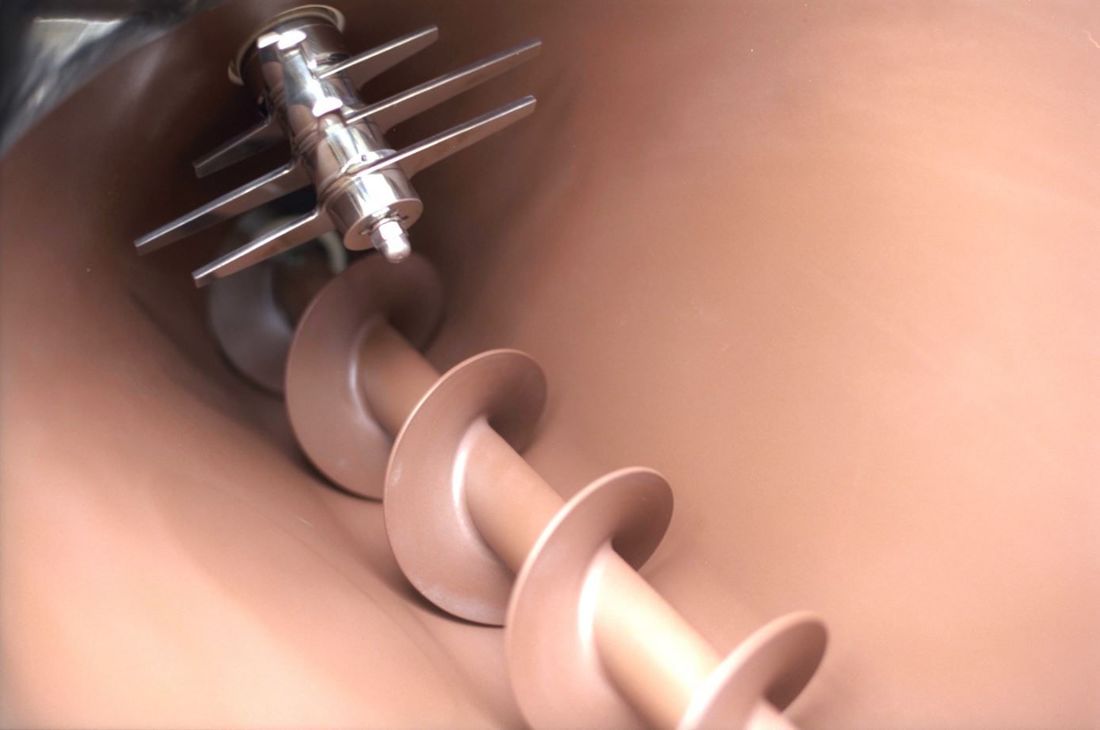

All our mixers are equipped with a tilting tank. Mixing is achieved by the joint action of the screw and the carefully designed tank. The screw conveys the powder (or granules) upwards which then comes back by itself under its own weight due to the inclination of the tank. All the lids of our mixers are either transparent or in stainless steel with windows for visual inspection during the mixing process.

|

Videos

|

Mixer Model: MP-50 (35L) with lifting column

Example of application: Mixing of salt for cosmetic application & coloring powder |

Mixer Model: MP-500 (440L)

Example of application: Mixing spices, cereals, etc… (Food industry) |

Examples of application

Food

|

Integration of two Prodima Mixers in a totally automatized environment

A major UK manufacturer of cooking sauces has installed two HLR-1200 Prodima mixers in its fully automated production lines. Both Prodima mixers with integral weighing system, cutters and vibrators, mix and homogenize the dry sauce ingredients. These are made out of powders, dried vegetables and sometimes small addition of liquids. The way the Prodima mixers work guarantees repeat flavour and consistent high quality in their sauces. The complete installation incorporates automatic loading, mixing and discharging, controlled overall by a fully integrated PLC system, allowing total flexibility, dependant on production requirements and finally, full retention of production data for record and analysis. |

|

Two MP Mixers integrated in a pilot Dry Mix plant

In the R&D Centre of an international producer, two heavy duty mixers HLR type, have been integrated in a Dry Mix line. They are being used for the manufacture of basic ingredients pre-mixes, such as cocoa, sugar and others, which later on during the process are being transformed. The loading of the mixer is performed semi-automatically and in part manually. When the mix is ready, the finished product is then pneumatically conveyed to the next step in the manufacturing chain. Our both Prodima mixers are running at the full satisfaction of our customer. |

Cosmetics

A mixer used to produce greasy eye shadow and make-up powder mixtures

|

A well-known company in Brazil became aware of our high-tech mixer during an international trade show thanks to its

Two days of trials run with three engineers on our 50 type lab-mixer (Internally coated with Teflon) convinced our customer about the efficiency of our system. The mixer is used to produce greasy eye shadow and make-up powder mixtures. An additional problem was that the mixed components were partly sticky. For most products, liquid additives have to be used. These very demanding products have to be mixed with high accuracy regarding colour distribution and fineness. The Prodima-Mixer MP 150 manages to mix and homogenize this product in a short time. |

Considering the special characteristics of the product, the mixer has been fitted with the following features:

|

Pharmaceutical

|

Installation (MP mixer) together with a Frewitt TC sizing mill

Mixer type: HLR 1200. Application: Mixing powders for veterinary products with injection of liquids (honey). This combination consists of a Prodima HLR 1200 pharmaceutical mixer, an intermediate container with discharge mechanism and a flexible conveyor; all used in a pharmaceutical production facility. The mobile mixer is loaded from the loading platform. At the end of the mixing cycle, the entire mix is emptied into the intermediate container from where the conveying system transfers the product homogeneously and dust-free to the TC mill, with the advantage that the mixer is immediately ready for a new batch. |